By clicking on different items, you can view their descriptions.

The XIMA Pump Series Drive is a specialized device designed specifically for controlling the speed of various types of pumps. It has been developed based on the expertise and experience of specialists in the field of water supply and HVAC systems.

One of the key features of this product is its dedicated functions and specialized software tailored for booster pump systems, enabling the simultaneous operation of multiple drives in Master/Slave mode.

In addition, this drive supports the control of:

Up to 5 pumps with variable speed

Up to 11 pumps with fixed speed, using a single drive and an external relay expansion card

Technical Features of XIMA Pump Series (P) Drives

Key Features of XIMA Pump Series (P) Drives

Different Models of XIMA Pump Series (P) Drives

Single-phase Models

0.37 kW

0.75 kW

1.1 kW

1.5 kW

2.2 kW

3.0 kW

Three-phase Models

0.75 kW

1.5 kW

2.2 kW

3.0 kW

4.0 kW

5.5 kW

7.5 kW

11.0 kW

15.0 kW

18.5 kW

22.0 kW

30.0 kW

| Series ۱۰۰ | ۱۰۰ |

| Series ۲۰۰ | ۲۰۰ |

| Series ۳۰۰ | ۳۰۰ |

| Series ۱۰۰ | ۱۰۰ |

| Series ۲۰۰ | ۲۰۰ |

| Series ۳۰۰ | ۳۰۰ |

| ۱۵۵*۹۵*۱۴۰ | Size A |

| ۲۰۶*۱۰۳*۱۶۰ | Size B |

| ۲۸۵*۱۳۲*۱۷۹ | Size C |

| ۴۴۸*۲۰۵*۱۹۸ | Size D |

| ۰.۳۷ (kW) | ۰۰۴ |

| ۰.۷۵ (kW) | ۰۰۸ |

| ۱.۱ (kW) | ۰۱۱ |

| ۱.۵ (kW) | ۰۱۵ |

| ۲.۲ (kW) | ۰۲۲ |

| ۳ (kW) | ۰۳۰ |

| ۴ (kW) | ۰۴۰ |

| ۵.۵ (kW) | ۰۵۵ |

| ۷.۵ (kW) | ۰۷۵ |

| ۱۱ (kW) | ۱۱۰ |

| ۱۵ (kW) | ۱۵۰ |

| ۱۸.۵ (kW) | ۱۸۵ |

| ۲۲ (kW) | ۲۲۰ |

| ۳۰ (kW) | ۳۰۰ |

| Single-phase | ۱ |

| Three-phase | ۳ |

Size A : 140

Size B : 160

Size C : 197

Size D : 198

Size A : 95

Size B : 103

Size C : 132

Size D : 205

Size A : 155

Size B : 206

Size C : 285

Size D : 448

Size A : 144

Size B : 194.5

Size C : 269.5

Size D : 426

Size A : 84

Size B : 91.5

Size C : 115

Size D : 159

The diagrams on the right illustrate the dimensions of the drive from various perspectives.

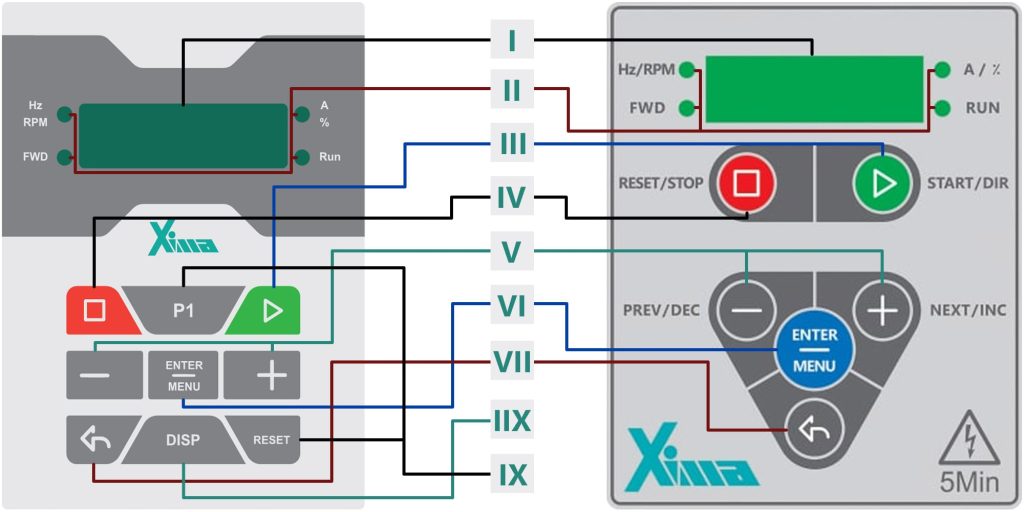

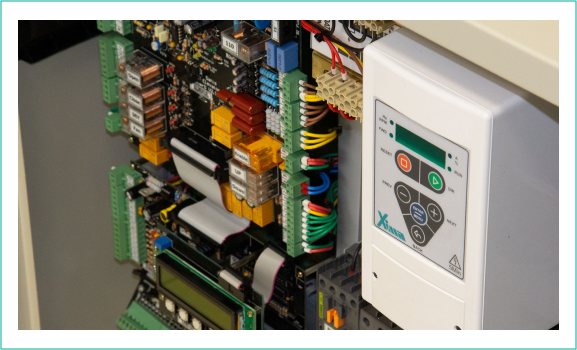

In this image, you can become familiar with the various parts of the Series (L) panel.

By clicking on different items, you can view their descriptions.

LCD

A 4-digit display for showing frequency, speed, current, load value, and for viewing and adjusting parameters.

LCD

صفحهنمایش ۴ رقمی و برای نمایش مقادیر فرکانس، دور، جریان، مقدار بار و مشاهده و تنظیم پارامترها.

LED

چهار عدد LED برای نمایش جهت چرخش موتور، نمایش جریان یا درصد بار، فرکانس یا دور موتور، استارت یا استپ بودن دستگاه.

NEXT/INCPREV/DEC

کلید افزایش/بعدی (NEXT/INC) و کلید کاهش/قبلی (PREV/DEC). در هنگام تنظیم پارامترها برای حرکت روی پارامترهای مختلف و یا تغییر مقدار یک پارامتر (در صورت انتخاب شدن پارامتر) به کار میرود. در ادامه توضیحات بیشتر را مشاهده خواهید نمود.

DISP (G۲۰۰)

حالت صفحه نمایش را تغییر میدهد.

P۱/RESET (G۲۰۰)

رزرو شده.

| Product Model | Power (kW) | Power (HP) | Dimensions (mm) | Size | Weight |

|---|---|---|---|---|---|

| P100A004-1 | 0.37 | 0.5 | 155 * 95 * 140 | A | Less than 1600 grams |

| P100A008-1 | 0.75 | 1 | 155 * 95 * 140 | A | Less than 1600 grams |

| P100B008-3 | 0.75 | 1 | 206 * 103 * 160 | B | Less than 2200 grams |

| P100A011-1 | 1.1 | 1.5 | 155 * 95 * 140 | A | Less than 1600 grams |

| P100B015-1 | 1.5 | 2 | 206 * 103 * 160 | B | Less than 2200 grams |

| P100B015-3 | 1.5 | 2 | 206 * 103 * 160 | B | Less than 2200 grams |

| P100B022-1 | 2.2 | 3 | 206 * 103 * 160 | B | Less than 2200 grams |

| P100B022-3 | 2.2 | 3 | 206 * 103 * 160 | B | Less than 2200 grams |

| P100B030-1 | 3 | 4 | 206 * 103 * 160 | B | Less than 2200 grams |

| P100B030-3 | 3 | 4 | 206 * 103 * 160 | B | Less than 2200 grams |

| P100B040-3 | 4 | 5.5 | 206 * 103 * 160 | B | Less than 2200 grams |

| P100B055-3 | 5.5 | 7.5 | 206 * 103 * 160 | B | Less than 2200 grams |

| P200C075-3 | 7.5 | 10 | 285 * 132 * 179 | C | Less than 3600 grams |

| P200C110-3 | 11 | 15 | 285 * 132 * 179 | C | Less than 3600 grams |

| P200C150-3 | 15 | 20 | 285 * 132 * 179 | C | Less than 3600 grams |

| P300D185-3 | 18.5 | 25 | 448 * 205 * 198 | D | Less than 10,800 grams |

| P300D220-3 | 22 | 29.5 | 448 * 205 * 198 | D | Less than 10,800 grams |

| P300D300-3 | 30 | 40 | 448 * 205 * 198 | D | Less than 10,800 grams |

| Product Model | Power (kW) | Input Voltage | Output Voltage | Input Current (A) | Output Current (A) |

|---|---|---|---|---|---|

| P100A004-1 | 0.37 | 220 V Single-phase 50–60 Hz | 220 V Three-phase 0–800 Hz | 5.6 | 3 |

| P100A008-1 | 0.75 | 220 V Single-phase 50–60 Hz | 220 V Three-phase 0–800 Hz | 9.8 | 5 |

| P100B008-3 | 0.75 | 380 V Three-phase 50–60 Hz | 380 V Three-phase 0–800 Hz | 3.2 | 3 |

| P100A011-1 | 1.1 | 220 V Single-phase 50–60 Hz | 220 V Three-phase 0–800 Hz | 12 | 6 |

| P100B015-1 | 1.5 | 220 V Single-phase 50–60 Hz | 220 V Three-phase 0–800 Hz | 18.5 | 9 |

| P100B015-3 | 1.5 | 380 V Three-phase 50–60 Hz | 380 V Three-phase 0–800 Hz | 5.4 | 5 |

| P100B022-1 | 2.2 | 220 V Single-phase 50–60 Hz | 220 V Three-phase 0–800 Hz | 22 | 11 |

| P100B022-3 | 2.2 | 380 V Three-phase 50–60 Hz | 380 V Three-phase 0–800 Hz | 7.6 | 7 |

| P100B030-1 | 3 | 220 V Single-phase 50–60 Hz | 220 V Three-phase 0–800 Hz | 34.7 | 16.5 |

| P100B030-3 | 3 | 380 V Three-phase 50–60 Hz | 380 V Three-phase 0–800 Hz | 9.7 | 9 |

| P100B040-3 | 4 | 380 V Three-phase 50–60 Hz | 380 V Three-phase 0–800 Hz | 10.8 | 10 |

| P100B055-3 | 5.5 | 380 V Three-phase 50–60 Hz | 380 V Three-phase 0–800 Hz | 14.2 | 13 |

| P200C075-3 | 7.5 | 380 V Three-phase 50–60 Hz | 380 V Three-phase 0–800 Hz | 21 | 19 |

| P200C110-3 | 11 | 380 V Three-phase 50–60 Hz | 380 V Three-phase 0–800 Hz | 28.9 | 26 |

| P200C150-3 | 15 | 380 V Three-phase 50–60 Hz | 380 V Three-phase 0–800 Hz | 40.3 | 36 |

| P300D185-3 | 18.5 | 380 V Three-phase 50–60 Hz | 380 V Three-phase 0–800 Hz | 45 | 40 |

| P300D220-3 | 22 | 380 V Three-phase 50–60 Hz | 380 V Three-phase 0–800 Hz | 54 | 47 |

| P300D300-3 | 30 | 380 V Three-phase 50–60 Hz | 380 V Three-phase 0–800 Hz | 72 | 63 |

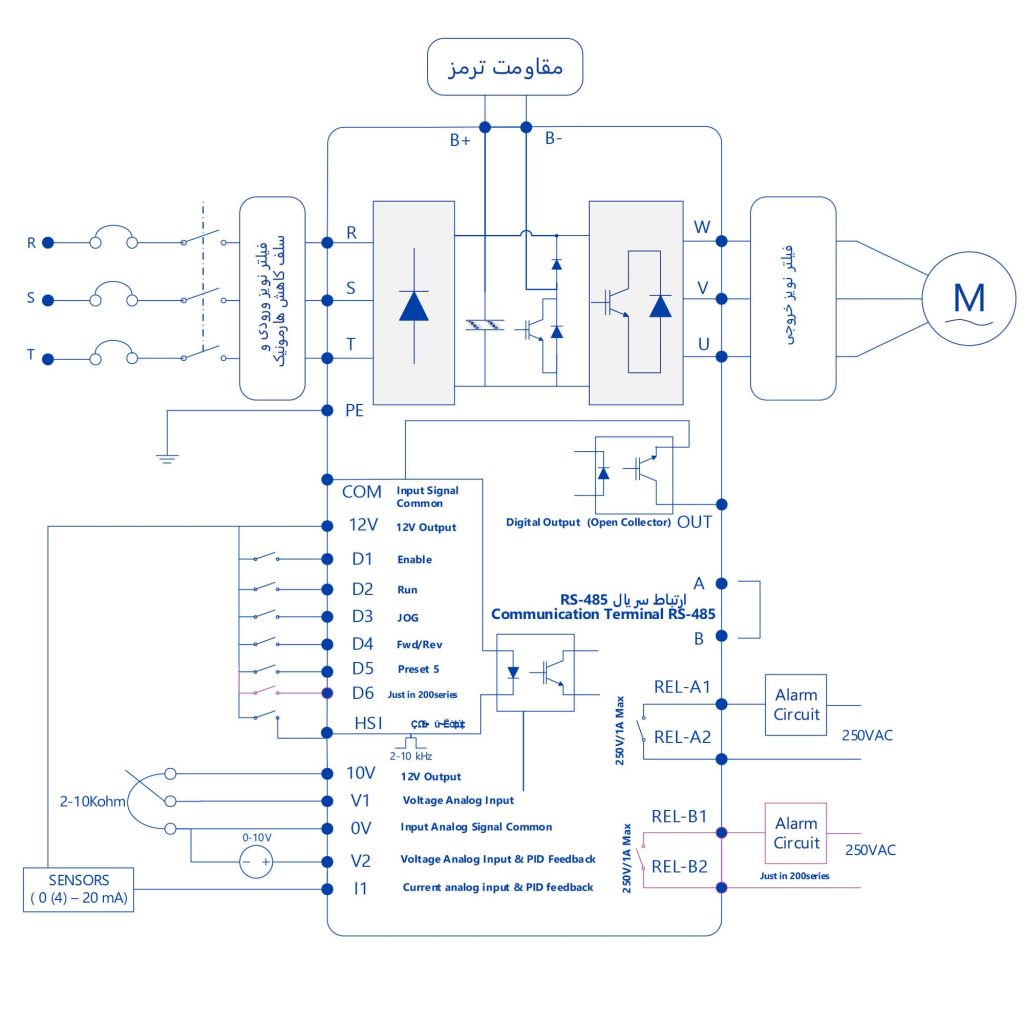

| PWM Frequency | 2 – 10 kHz | ||

|---|---|---|---|

| Analog Voltage Input Impedance | 14.3 kΩ | ||

| Analog Current Input Impedance | 150 Ω | ||

| Digital Input Impedance | 9.5 kΩ | ||

| Efficiency | % 97.5 | ||

| Number of Inputs and Outputs | 2 Analog Voltage Inputs 1 Analog Current Input 5 Digital Inputs | ||

| Enclosure Standard | IP 20 | ||

|---|---|---|---|

| Enclosure Structure | Reinforced Plastic and Metal | ||

| Accessories Included | Catalog Screws and Washers Mounting Template Mini Screwdriver | ||

| RS-485 Port | Available (1× LAN Port, 1× Serial Port) | ||

| Detachable Keypad | Coming Soon | ||

| Country of Manufacture | Iran | ||

| Display | 4 Seven Segments 4 LEDs | ||

|---|---|---|---|

| Keypad | 6 (8) Keys | ||

| Output Frequency Range | 0-800 Hz | ||

| Frequency Resolution | 0.001 Hz (0.1 Hz display) | ||

| PWM Frequency | 2.0 – 10.0 KHz | ||

| PWM Modulation | Space Vector | ||

| PWM Resolution | > 11bit | ||

| ADC Resolution | 12 bit / 4 Msps | ||

| DSP | 32 bit Motor Control | ||

| Control Sampling Frequency | 1000 Hz | ||

| Input Frequency | 47-63 Hz | ||

| Input Voltage | 200 – 260 (1PH) 330 – 460 (3PH) | ||

| Output Voltage | 0 – Input Voltage | ||

| Efficiency (PF=1 , Vout=Vin) | > %97.5 | ||

| Phase Short Circuit Protection | To phase Ground +Bus -Bus | ||

| Brake | DC Brake Dynamic Brake | ||

| Voltage Limit Threshold (if enabled) | 380 V (1PH) 700 V (3PH) | ||

| Brake ON Voltage | 370 V (1PH) 690 V (3PH) | ||

| Brake OFF Voltage | 365 V (1PH) 680 V (3PH) | ||

| Over Voltage Fault | 400 V (1PH) 720 V (3PH) | ||

| Current Limit Threshold | Adjustable | ||

| Over Current Threshold | 2x Drive Rated Current | ||

| Analog Voltage Input Impedance | 14.3 Kohm | ||

| Analog Current Input Impedance | 150 ohm | ||

| Digital Input Impedance | 9.5 Kohm | ||

| 12V Output Voltage | 12-14 V | ||

| 12V Supply Output Impedance | 5 ohm (PTC protected) | ||

| Torque Control Response | < 200ms | ||

| Start Torque | 150% Rated Output Torque 0.5 Hz | ||

| Torque Control Precision | ± 0.5% Rated Output Torque | ||

| Ambient Temperature | -10 < Ta < 50 C | ||

|---|---|---|---|

| Humidity | < %85 | ||

| Altitude | Below 1000m Without Derating | ||

| Vibration | 0.5 g X, Y, Z | ||

| Stall Prevention | Acceleration Deceleration Operation | ||

|---|---|---|---|

| Overcurrent | 180% Rated Current For 30 s | ||

| Overload Warning | 150% Rated Current For 1 min | ||

| Motor Thermal Protection | Overload Curve | ||

| Overload Curve | VDC > 750 V (380V Class) VDC > 390 V (220V Class) | ||

| Undervoltage | VDC < 350 V (380V Class) VDC < 200 V (220V Class) | ||

| Overheat | Protection By Thermistor | ||

| Grounding | Protection By DC Current Sensor | ||

| Phase loss | Input – Output | ||

| Momentary Power Loss | 10ms at Nominal Voltage and Power | ||

A drive or motor speed controller is used to regulate the speed of AC electric motors (both single-phase and three-phase) across various industrial applications. Drives can continuously vary the motor speed from zero up to several times the motor’s rated speed.

Speed control in electric motors not only enhances the flexibility of industrial processes but also contributes significantly to energy savings in many applications. Additionally, drives substantially reduce the inrush current drawn from the power supply during motor startup, often lowering it to well below the motor’s nominal current.

The XIMA P Series drives, capable of operating multiple drives simultaneously and available in 15 different models with diverse power ranges, are designed for use in applications such as residential pumps, industrial pumps, booster pumps, and more.

Residential Pumps

Booster Pumps

Industrial Pumps

Xima Knowledge-Based Company, with a mission to promote a knowledge-based economy and contribute to the development of our country, annually manufactures over 30,000 smart Variable Frequency Drives (VFDs), making it the largest and only exporter of VFDs to more than 13 countries worldwide.

The creation of indigenous knowledge by Iranian engineers and specialists, direct employment for over 250 individuals, foreign currency generation, and prevention of currency outflow are among our most significant achievements within the knowledge-based ecosystem.